Development

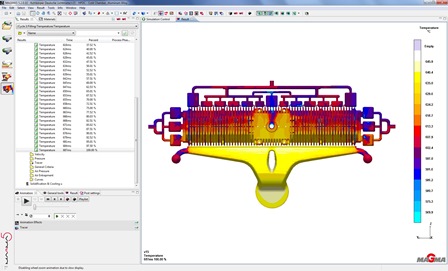

Optimum die casting processes are characterized by casting conditions that avoid gas inclusions, cold runs and porosity, while at the same time offering optimum filling characteristics and short cycle times. Economical production aims at optimal mold tempering, long mold service life, the lowest possible cycle material and ideally adjusted machine parameters. With casting process simulation, die casters gain a deeper understanding of their processes and can adjust mold design, production parameters and casting technology to produce castings of optimum quality in an economical, robust manufacturing process (Source Magma).

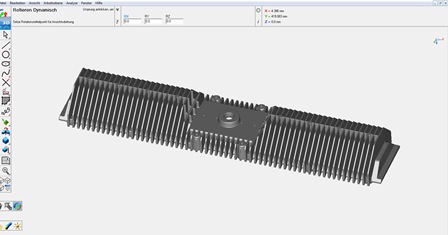

With the Magmasoft® simulation software, we simulate the functioning of tools even before mold production. This enables us to design the tools correctly from the start, to produce parts in the best possible quality right away, and to optimize lead times for our projects. In addition, we can use the program to determine if an article is not designed for die casting.

All machining fixtures for our machining centers as well as all sawing fixtures are designed and manufactured in-house. Depending on the requirements of the part, these can be clamped hydraulically or mechanically, so that even powder-coated parts can be clamped for machining.

.jpg)